DIY Teardrop Build Mistakes

Learn From My Mistakes

My biggest mistakes with this trailer build & the most important components to focus on in a teardrop build are in the Expert Tips video lesson.

After more than a decade and a half of teardrop trailer production, I know so much more that I wish I had known in 2007.

Learn from ALL of my mistakes -not just the ones from this trailer.

Some Big Changes to the jPod

SO many Galley Hatch Rebuilds

I put three different galley hatch doors on my first teardrop until the design you see in this photo was finalized. The curve of the hatch was a bit tricky and the early versions were difficult to keep square, light, and strong.

We offer a galley door kit for home builders so they can get it right the first time.

Different Axle

I’d certainly put Torsion Axle or Timbren on this trailer if I built it again. The spring axle was too responsive and didn’t offer independent suspension.

Both the Timbren and Torsion axles offer independent suspension (left tire and right tire are not tied to each other). Plus, they both rely on a poly bushing that reacts progressively to pressure which keeps the trailer smoother on the road/trail and safer.

Use a good set of teardrop camper plans:

- SAVE TIME – Figuring out how raw materials will fit together and which ones are the best is time-consuming. It shouldn’t take hours and many websites to find the most important things you need to know before building!

- SAVE MONEY – Minimize building material waste with cut lists that efficiently use as little material as possible. Get just the right parts to build it right and build it once.

- MORE CONFIDENCE – peace of mind that the trailer build is watertight and made for a lot of use.

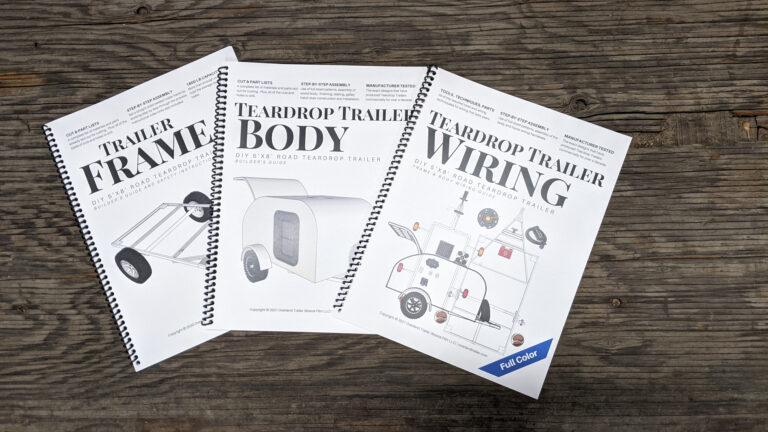

Need ALL of the Overland Teardrop Trailer Plans?

Some Smaller Changes to the jPod:

- Add rock-guards around trailer lights.

- Build a MUCH lighter Frame (design Your Frame Here).

- Interior cabinetry should have been taller by 6″ and deeper by 2″.

- A full-time sleep Futon Mattress instead of camping foam mattresses.

- Sheet Aluminum exterior – I could have saved hours of maintenance, touch-up, and fuss through the years that I had this trailer. Eventually, I did put Aluminum on the outside.

- Change the Body profile. I ended up tearing the galley hatch off, tearing off about 1 foot of the roof, and reshaping the profile of the trailer to make the transition from roof to galley hatch a smoother radius. That could have been avoided with a good set of tested plans.

There’s more but those are the big changes I’d make.

Take Your First Step

Get your first set of Overland Teardrop Trailer Plans and start building your own teardrop camper. I suggest starting with the Teardrop Camping Trailer Plans – Bundle.

Need ALL of the Overland Teardrop Trailer Plans?